Bentley has just announced that the W12 engine for the first customer Mulliner Bacalar has now been assembled, and it has completed a series of exhaustive production tests.

These tests were carried out at Bentley’s center of excellence in Crewe and were carried out to meet high customer standards. The automaker claims that W12 is the most advanced 12-cylinder engine in the history of automobiles.

The W12 has been developed for the $1.9 million Bentley Bacalar Continental GT Convertible. The W12 engine was first introduced by Bentley in 2003, and its latest generation was first featured in the Bentayga SUV launched in 2016. Bentley says that thanks to engine refinements, the power output has increased by 27%, while total torque has increased by 38%.

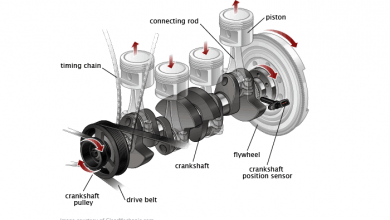

To achieve this, Bentley optimized the crankcase, upgraded the cooling and oil systems, made the injection and combustion processes more effective, also adding twin-scroll turbocharging technology. As of now, the twin-turbo 6.0-litre W12 engine produces 650 hp and 667 lb-ft of torque, and those are some huge numbers.

Bentley also stated that it takes a team of 45 people over 6.5 hours to build a Bacalar W12, subjecting it to three rigorous tests that last for over an hour. These tests are a part of Bentley’s quality control, and this is why these engines are among the best in the industry.

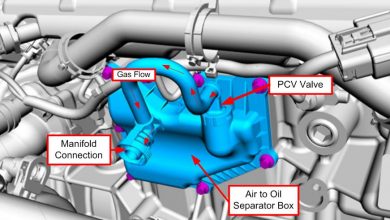

The first test is conducted for discovering leakages, and it is done after the engine has been assembled to a point where fuel, oil, and water systems can be closed. In the test, each of these systems is subjected to pressure, allowing Bentley to detect any fault.

The second one is called the “Cold Test,” and it is the most advanced test of them all. In this test, the engine is mounted on a testbed connected to a large electric motor via the crankshaft. The 15-minute test allows Bentley to measure 600 different properties and characteristics of the engine. The test is carried out at a low running speed of 120 RPM enabling the team to notice even the slightest inconsistencies.

The third and final test is called the “Hot Test.” It is carried out after the engine has been assembled completely. This test simulates real-world usage in the car, and during it, a UV dye is also poured into the engine to identify any leaks.

Each W12 engine is then tested for at least 21.5 minutes, running at 3,800 RPM with a maximum load of 221 lb-ft. Bentley established three craft beds in 2002, and ever since, more than 100,000 engines have been assembled and tested at the facility.

In the Bacalar, the W12 engine would be paired with an eight-speed dual-clutch transmission, allowing it a maximum speed of 200 mph. Thanks to quick gear shifts, the Bacalar could go from 0 to 60 mph in just three and a half seconds.

[outofthebox dir=”/aliraq blog/bentley ready to showcase” account=”dbid:AAAhSvgLKD_3VVaz5A2C-Bx6QY2rE3fxe3U” mode=”gallery” viewrole=”administrator|author|contributor|editor|subscriber|pending_user|guest” downloadrole=”all” search=”0″]

Bentley Motors is the most sought-after luxury car brand in the world. The company’s headquarters in Crewe is home to all of its operations including design, R&D, engineering, Mulliner and production of the company’s three model lines, Continental, Flying Spur, and Bentayga. The combination of fine craftsmanship, using skills that have been handed down through generations, alongside engineering expertise and cutting-edge technology is unique to UK luxury car brands such as Bentley. It is also an example of high-value British manufacturing at its best. Bentley employs around 3,000 people at Crewe.

- Download 2014-2018 Lexus RC F Wiring Diagrams

- Download 2014-2016 Honda Odyssey Wiring Diagrams

- Download 2010 Ford Ranger Repair Manual

- Download 2013-2016 Hyundai Genesis Repair Manual

- Download 2014-2016 Jeep Compass and Patriot Repair Manual.

- Download 2008-2010 Toyota Scion xD Repair Manual.

- Download 2015-2018 Ford Focus MK3 Repair Service Manual.