Symptoms of a Bad or Failing Crankshaft Position Sensor

Common signs of a faulty crankshaft position sensor include issues starting the vehicle, intermittent stalling, and the Check Engine Light coming on.

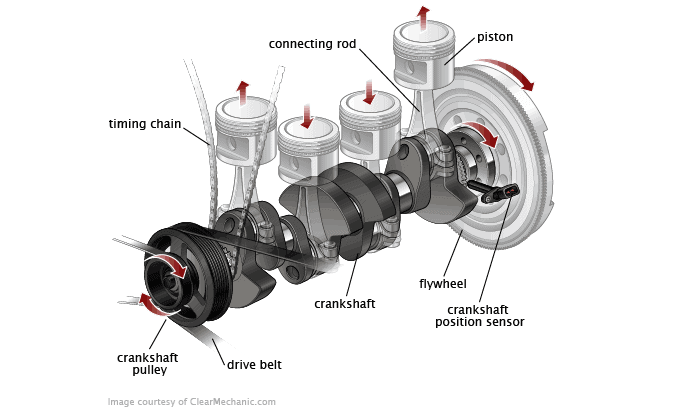

The Crankshaft Position Sensor is an engine management component found on virtually all modern vehicles with internal combustion engines. It monitors the position and rotational speed of the crankshaft and sends the information to the engine control unit so it can make appropriate adjustments based on operating conditions. The crankshaft speed and position are some of the most important parameters used in engine management calculations, and many engines cannot run if the crankshaft position sensor is not providing an accurate signal.

Problems with the crankshaft position sensor can be linked to several issues. 2 common causes include:

1- Overheating Engine. The excessive build-up of heat in the engine can lead to crankshaft sensor damage by melting the plastic covering.

2- Circuitry Problems. A faulty voltage or loose, worn-out, or damaged wiring can disrupt the signals sent to and from the crankshaft sensor, causing it to have issues.

3- Driving with a failing crankshaft position sensor can be difficult and potentially dangerous. It could lead to long-term vehicle damage and expensive repairs, or even stop the car from working at all. Usually, a problematic crankshaft position sensor will produce any of the following 7 symptoms that alert the driver of a potential problem that should be serviced.

1. Issues Starting the Vehicle

The most common symptom associated with a bad or failing crankshaft position sensor is difficulty starting the vehicle. The crankshaft position sensor monitors the position and speed of the crankshaft and other parameters that play an important role when starting the engine. If the crankshaft position sensor is having a problem, the vehicle may have intermittent starting issues or not start at all.

2. Intermittent Stalling

Another symptom commonly associated with a problematic crankshaft position sensor is intermittent stalling. If the crankshaft position sensor or its wiring has any issues, it can cause the crankshaft signal to be cut off while the engine is running, which can cause the engine to stall. This is usually a sign of a wiring problem. However, a bad crankshaft position sensor can also produce this symptom.

3. Check Engine Light Comes On

Another issue of a potential problem with the crankshaft position sensor is an illuminated Check Engine Light. If the computer detects a problem with the crankshaft position sensor’s signal, it will activate the Check Engine Light to alert the driver of the problem. A Check Engine Light can also be set off by a wide variety of other issues. Having the computer scanned for trouble codes is highly recommended.

4. Uneven Acceleration

With inaccurate input coming from the crankshaft position sensor, the engine control unit can’t make the adjustments to spark timing and fuel injection as the engine speed increases. Slow or uneven acceleration can result from a lack of accuracy and make it difficult to maintain a constant speed.

5. Engine Misfires or Vibrates

Should you feel or hear a brief stutter in the engine, it may be a sign of misfiring cylinders from a bad crankshaft position sensor. A failing crankshaft position sensor cannot provide the right information about piston positioning in the engine, causing a cylinder to misfire. This could also occur from faulty spark plug timing, but if the spark plug checks out, then the crankshaft sensor is likely the source.

6. Rough Idle and/or Vibrating Engine

Another sign of a crankshaft position sensor problem is rough idling. While idling at a red light or otherwise stopped, you may notice the engine grinding or vibrating. When this happens, it means the sensor is not monitoring the crankshaft’s position, leading to vibrations that affect overall engine power. The shaking can also interfere with the engine’s tracking of mileage. Any out-of-the-ordinary vibrations should be inspected by a mechanic as soon as possible.

7. Reduced Gas Mileage

Lacking accurate timing information from the crankshaft position sensor, fuel injectors won’t pump gas into the engine efficiently. The engine will use more gas than it needs on short and long drives, reducing overall fuel economy. Have a mechanic inspect the sensor — as insufficient fuel economy can occur from other issues as well.

The crankshaft position sensor is critical to proper engine functionality and performance due to the vital signal it provides for engine calculations. Issues with the crankshaft sensor can quickly lead to problems that affect the drivability of the vehicle. For this reason, if you suspect your crankshaft position sensor has an issue, have the vehicle inspected by a professional mechanic right away. They will be able to diagnose your car and replace your crankshaft position sensor if necessary.