What is OBD-II Diagnostic Interface?

It is a vehicle’s electronic troubleshooting system. Dating back to the late 1960s when the first diagnostic computer was utilized in a Volkswagen, the OBD system reports trouble codes (DTCs) by plugging in an ODB scanner that reads them.

Initially only used by auto mechanics, today, anyone can plug an OBD scanner into the vehicle’s OBD port under the dashboard to find out why the Check Engine Light is on. Units may only display codes, while others report more information, and some can even predict failure. See car memory saver.

OBD II

Starting in the late 1960s, there were different diagnostic interfaces from Volkswagen, Datsun and General Motors, but in 1991, California needed a basic set, loosely referred to as OBD-I. However, it was not until 1996 that OBD was standardized for all U.S. vehicles with the OBD-II specification and standards.

OBD-III

OBD-III has been proposed to report emission failures to a regulatory agency, which requires the owner to have the vehicle serviced before the inspection due date. It was very controversial, OBD-III is seen as an invasion of privacy and as of 2022 has not been implemented.

Plugged into the OBD port, T-Mobile’s SyncUp sends maintenance notifications in real-time to the user’s smartphone. Also used for vehicle tracking, trip history and driving behaviour, it can even generate Wi-Fi for passengers (see Wi-Fi hotspot).

Is My Car Equipped With OBD-II?

On Board Diagnostics (OBD) is required on all cars and light trucks in the United States from 1996 onward. OBD-II is a set of specifications for monitoring and reporting on engine performance in modern automobiles. Diesel (compression ignition) vehicles were not required to support OBD until 2004. Some pre-2001 petrol vehicles and pre-2004 diesel vehicles have 16-pin connectors but they may not be OBD-II or EOBD compliant.

Where is an OBD-II connector Interface?

Locating the OBD connector can be a problematic task as car manufacturers tend to hide away the socket. Normally, you can find the OBD connector located on the driver’s side of the passenger compartment near the center console. Occasionally it’s located in the driver’s foot well, under the steering wheel, behind panels in the dashboard fascia and in the central area between the driver’s seat and the passenger seat. Some connectors have been located behind ashtrays, under the passenger seat and even over by the passenger’s door.

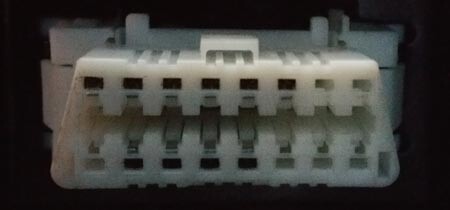

OBD-II connector must have pins 4, and 5 for ground connections and pin 16 for power supply from the battery.

The connector exists in two versions, type A for 12 Volt vehicles and type B for 24 Volt vehicles.

Why OBD DTC?

Prior to OBD, vehicle manufacturers did not standardize DTCs (Diagnostic Trouble Code). OBD-I begins standardized DTC’s OBD-II and adds specific tests to determine the vehicle’s emission performance OBD-III adds more features and is in the regulatory development phase as we have mentioned earlier.

If the vehicle’s onboard diagnostic system detects a malfunction, a DTC corresponding to the malfunction is stored in the vehicle’s computer, as well as real-time data from the sensors connected to the onboard computer. In addition, the OBD-II interface provides a means to clear the DTCs once maintenance has been completed.

A service technician can retrieve the DTC, using a scan tool, and take appropriate action to resolve the malfunction. Prior to the advent of digital powertrain control modules, which is the technical enabler for the OBD feature, repairing a vehicle relied solely upon the technician’s skill and service literature from the auto manufacturer.

OBD-II connector specifications

The OBD-II specification provides for a standardized hardware interface – the female 16-pin (2×8) J1962 connector. Unlike the OBD-I connector, which was found under the hood of the vehicle, the OBD-II connector is located on the driver’s side of the passenger compartment near the center console.

Refer to related pinouts for vendor-specific OBD-2 pinouts.

| Pin | Signal | Description |

| 1 | Manufacturer Discretion | |

| 2 | J1850 Bus+ | SAE J1850 PWM and VPW |

| 3 | Manufacturer Discretion | |

| 4 | CGND | GND |

| 5 | SGND | GND |

| 6 | CAN High | CAN ISO 15765-4 and SAE J2284 |

| 7 | ISO 9141-2 K-LINE | K-Line of ISO 9141-2 and ISO 14230-4 |

| 10 | J1850 Bus- | SAE J1850 PWM only |

| 14 | CAN Low | CAN ISO 15765-4 and SAE J2284 |

| 15 | ISO 9141-2 L-LINE | K-Line of ISO 9141-2 and ISO 14230-4 |

| 16 | +12V or +24V | Battery power |

There are five protocols in use with the OBD-II interface, and often it is possible to make an educated guess about the protocol in use based on which pins are present on the J1962 connector:

OBD-II Protocols

SAE J1850 PWM (41.6 kbaud, standard of the Ford Motor Company)

pin 2: Bus-

pin 10: Bus+

High voltage is +5V

Message length is restricted to 12 bytes, including CRC Employs a multi-master arbitration scheme called Carrier Sense Multiple Access with Non-Destructive Arbitration (CSMA/NDA)

SAE J1850 VPW (Variable Pulse Width) (10.4/41.6 kbaud, standard of General Motors)

pin 2: Bus+

Bus idles low

High voltage is +7V

Decision point is +3.5V

Message length is restricted to 12 bytes, including CRC Employs CSMA/NDA

ISO 9141-2. This protocol has a data rate of 10.4 kbaud, and is similar to RS-232.

ISO 9141-2 is primarily used in Chrysler, European, and Asian vehicles.

pin 7: K-line

pin 15: L-line (optional)

UART signaling (though not RS-232 voltage levels)

K-line idles high

High voltage is Vbatt

Message length is restricted to 12 bytes, including CRC

ISO 14230 KWP2000 (Keyword Protocol 2000) used by most European and Asian manufacturers.

Alfa Romeo, Audi, BMW, Citroen, Fiat, Honda, Hyundai, Jaguar (X300, XK), Jeep since 2004, Kia, Land Rover, Mazda, Mercedes, Mitsubishi, Nissan, Peugeot, Renault, Saab, Skoda, Subaru, Toyota, Vauxhall, Volkswagen (VW) since 2001, Volvo to 2004

pin 7: K-line

pin 15: L-line (optional)

Physical layer identical to ISO 9141-2

Data rate 1.2 to 10.4 kbaud

Message may contain up to 255 bytes in the data field

ISO 15765 CAN (250kbit/sec or 500kbit/sec)

pin 6: CAN High

pin 14: CAN Low

Used in most modern vehicles.

Note that pins 4 (battery ground) and 16 (battery positive) are present in all configurations. Also, ISO 9141 and ISO 14230 use the same pinout, thus you cannot distinguish between the two simply by examining the connector.

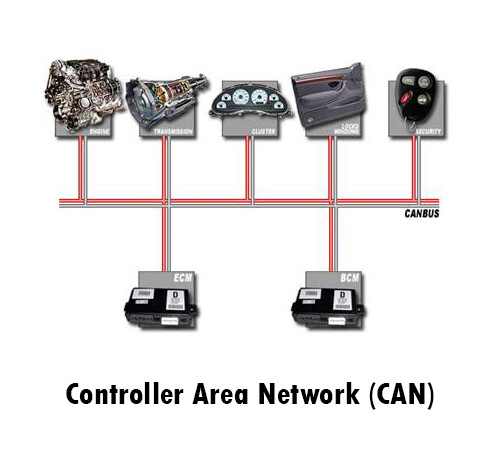

What is OBD-II CAN bus?

The CAN bus is a bus system with a data transfer rate of up to 1 Mbit/s which permits serial data exchange between control units. Two-wire cable networking enables the engine control unit to communicate with the gearbox control unit for example. Each control unit is connected to the bus by way of a CAN interface (bus controller + bus transceiver) and initially checks whether the data packets sent via the bus are of relevance to it.

The CAN bus is simply a pair of wires, often twisted around each other, running around the vehicle and terminated at either end of the two-wire network with resistors of 120 Ohms. The only components connected to the CAN bus are the electronic control units (nodes). Other components, such as sensors, motors, light bulbs, switches, etc. are wired only to the electronic control units. Some vehicles have a CAN bus system alongside the ISO/KWP2000 system. A vehicle which uses CAN bus for on-board diagnostics can only respond to an OBD-II request from a tester which uses CAN bus. From the model year 2008 vehicle manufacturers must use the OBD protocol specified in ISO 15765, also known as Diagnostics On CAN.

Modern cars are filled with any number of electronic systems. It is not uncommon for luxury class cars to have as many as 60 control units these days. Many of these electronic systems also have to communicate with one another. The extensive range of control units to be networked more or less rules out conventional wiring.

CAN bus used in Ford, Mazda, Volvo and most other cars since 2004. The CAN protocol is a widespread standard outside of the automotive industry and is making significant in-roads into the OBD-II market share. By 2008, all vehicles sold in the US will be required to implement the CAN bus, thus eliminating the obscurity of the existing five signalling protocols.

Two wires of CAN bus, CAN-H and CAN-L, will have the same voltage when idle (about 2.5V), or a voltage difference of 2V when a signal is placed on the CAN bus. When a signal is placed on the CAN bus the CAN-H line is at a higher voltage than the CAN-L line. Each electronic control unit have its own CAN identity code, like an address (may respond to several CAN id codes). If an electronic control unit is to communicate to another it will need to know the CAN identity code of the recipient.

A simple check to see if the CAN bus is in use in a vehicle, and accessible via the OBD socket, is to connect a resistance meter across pin 6 and pin 14. Due to the combined resistance of the two termination resistors at 120 Ohms each the overall resistance should be read as 60 Ohms.

OBD-II provides access to numerous data from the ECU and offers a valuable source of information when troubleshooting problems inside a vehicle. The SAE J1979 standard defines a method for requesting various diagnostic data and a list of standard parameters that might be available from the ECU. The various parameters that are available are addressed by parameter identification numbers or PIDs which are defined in J1979. For a list of basic PIDs, their definitions, and the formula to convert raw OBD-II output to meaningful diagnostic units, see OBD-II PIDs.

Here are some schemes of OBD-II diagnostic cables

OBD-2 ISO-9141-2, KWP2000 K-Line, L-Line RS-232 cable

- pin 7: K-line

- pin 15: L-line (optional)

- Physical layer identical to ISO 9141-2

- Data rate 1.2 to 10.4 kbit/s

- High signal voltage level: +12V (min/max 9.60 to 13.5)

- The message may contain up to 255 bytes in the data field

RS-232 to ISO-9141 cable scheme

OBD-2 ISO 9141-2 (14230-4, KWP2000) simple RS-232 cable

ISO 9141-2. This protocol has an asynchronous serial data rate of 10.4 kbit/s. It is somewhat similar to RS-232; however, the signal levels are different, and communications happen on a single, bidirectional line without additional handshake signals. ISO 9141-2 is primarily used in Chrysler, European, and Asian vehicles.

- pin 7: K-line

- pin 15: L-line (optional)

- UART signalling

- K-line idles high, with a 510-ohm resistor to Vbatt

- The active/dominant state is driven low with an open-collector driver.

- Message length is Max 260Bytes. Data field MAX 255.

OBD-II universal ISO 15765-4 CAN, SAE J1850 PWM, SAE J1850 VPW, ISO 9141-2, ISO 14230-4 and SAE J1939

This device is a microcontroller which is designed to interface a personal computer or laptop with a vehicle’s On-Board Diagnostic (OBD-II) interface. It is planned to work with all protocols used by vehicle manufacturers to implement the OBD-II system as defined by SAE and ISO specifications. The OBD-II system became compulsory for 1996 and up vehicles, but some vehicles were already fully or partially compatible with OBD II requirements prior to 1996.

The chip is not suitable for earlier vehicles such as OBD-I. The device is intended to function as a simple scan tool and is capable of sending and receiving any OBD-II message defined in SAE J1979 for any of the three types of OBDII bus implementations (PWM, VPW, ISO 9141-2). It can also be used as an affordable interface for custom instrumentation monitoring various vehicle parameters such as speed, RPM, coolant or intake air temperature, engine load, intake air flow rate, etc.